Clarion Synthetic Refrigeration Fluid 68

MSRP:

Now:

$2,140.70

Current Top Sellers

LubeCon ® I/M Dry Film Conveyor Lubricant - 5 Gallon Pail

MSRP:

Now:

$356.07

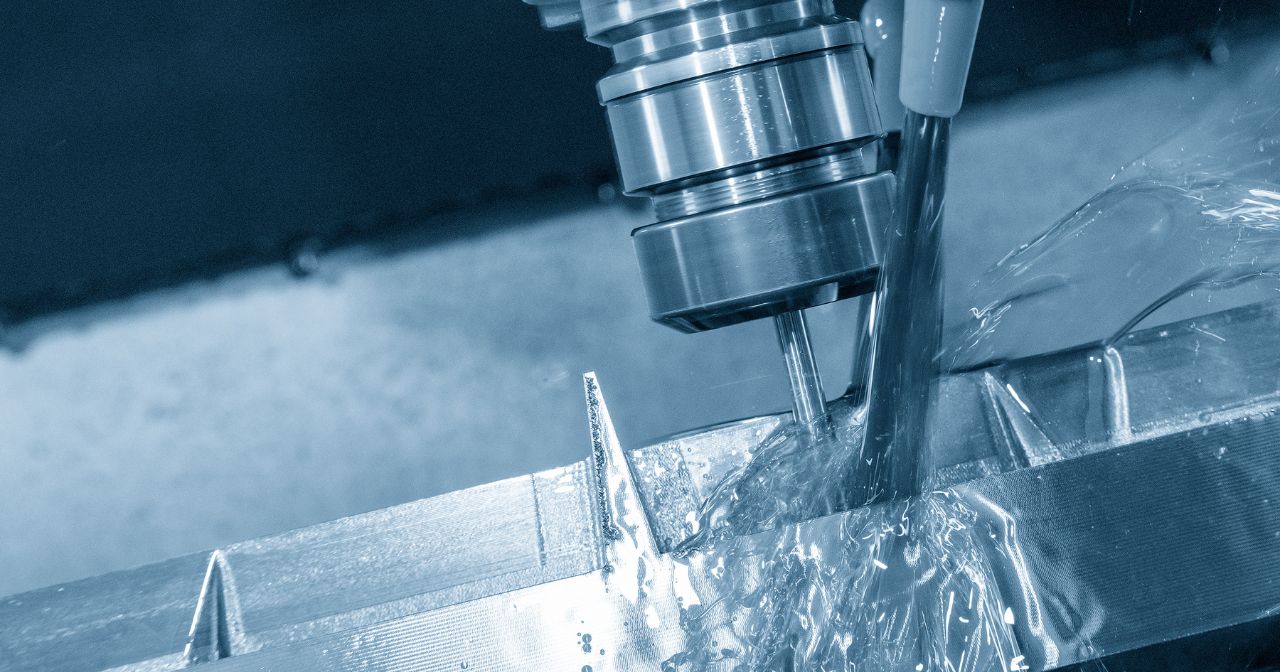

Castrol Syntilo 9930 Synthetic Coolant - 5 gal Pail

MSRP:

Now:

$233.69

LubeCon ® I/M 200 Dry Film Conveyor Lubricant - 5 Gallon Pail

MSRP:

Now:

$377.05

Castrol Syntilo 9918 Synthetic pH Neutral Coolant - 5 Gallon Pail

MSRP:

Now:

$291.39

Castrol Hysol MB 50 Semi-Synthetic Coolant - 55 gl Drum

MSRP:

Now:

$2,066.95

Sani Professional Sanitizing Multi-Surface Wipes (12/72 wipe Case)

MSRP:

Now:

$91.92

Cajun Kleen Cajun Brown Industrial Strength Cleaner 5 Gallon Pail

MSRP:

Now:

$78.00

New Products

Shell Rotella T4 Triple Protection 15W-40 CK4

MSRP:

Now:

$28.68

Shell Rotella T4 Triple Protection 10W-30 CK4

MSRP:

Now:

$28.41